- Home

- About

- Our Products

-

- Acoustic Enclosure Manufacturer

- Acoustic Enclosure

- Acoustic Enclosure for Machines

- Acoustic Enclosure for DG set

- Acoustic Enclosure for Power Plant

- Acoustic Enclosure for Turbine

- Acoustic Enclosure for Blower

- Acoustic Enclosure for Fin Press

- Acoustic Enclosure for Compressor

- Acoustic Enclosure for Chilller

- Acoustic Enclosure for Punch Press

- Automotive Noise Test Booth

- Noise Test Booth

- NVH Test Chamber

- Anechoic Chamber

- Audiometric Chammber

- Semi Anechoic Chamber

- Metallic Anechoic Wedges

- Mini/portable Anechoic Chamber

- Engine Test Cell Acoustic Treatment

- Room Acoustic Treatment

- work pods

-

- Sliding Folding Partition Manufacturer

- Acoustic Sliding Folding Partition

- Glass Sliding Folding Partition

- Vertical Fold Partition

- Semi Automatic Sliding Folding Partitions

- Acoustic Louver/Silencer Manufacturer

- Acoustic Louver For Chiller

- Acoustic Louver For Cooling Tower

- Industrial Fan Silencer

- Air Intake And Discharge Silencer

- Sand Trap Louver

- Sound Attenuator

-

- Projects

- Blog

- Clients

- Contact us

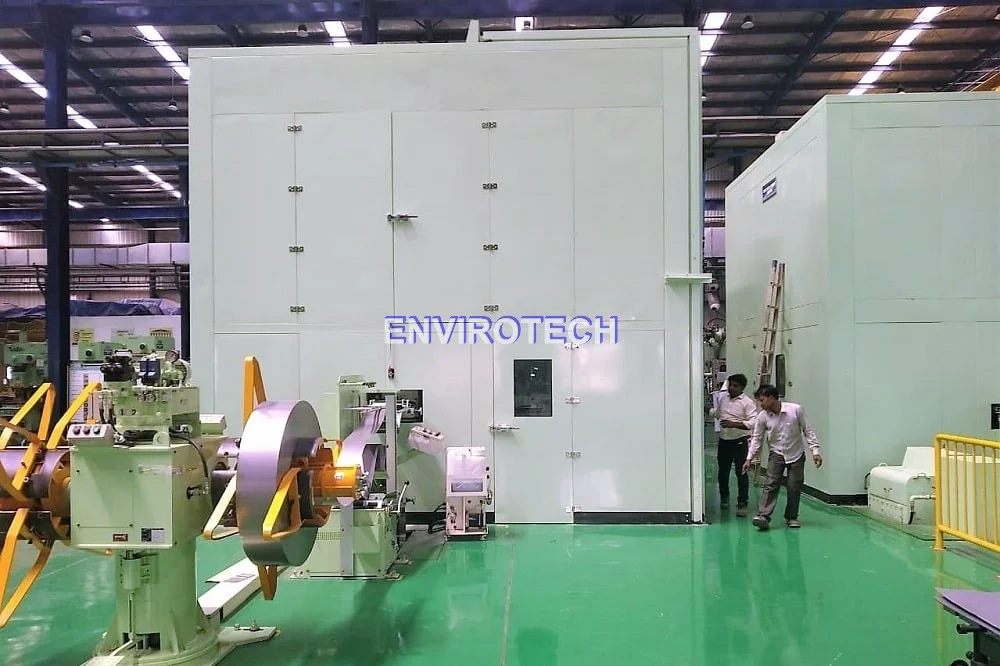

Acoustic Enclosure Revolutionizing Noise Control

Noise pollution management is, therefore, a most significant topic in workplace safety and environmental compliance in today's industries. Acoustic Enclosure is an effective source to eradicate or lessen unwanted noise generated by machines and other installations. At Envirotech Systems Ltd, we are dedicated to designing and manufacturing the top-notch quality of acoustic enclosures to provide maximum soundproof and operational efficiency. With the guidance of our experience as an Acoustic Enclosure Manufacturer in India, we cater to solutions required by different industries.

What is an Acoustic Enclosure?

An Acoustic Enclosure can be defined as a covering used to insulate sound and thus to minimize sound emissions from machinery, blowers, etc. The materials used in such enclosures are high-grade materials that absorb sound waves by reducing vibrations to provide a quieter environment. Advanced sound-reducing technologies can be integrated into enclosures catering to industries intending to be within the regulatory compliance limits of noise emission as well as providing noise comfort to employees.

Key Features of Acoustic Enclosures

Noise Attenuation: Exclusive New Design to Minimize Noise Levels.

1. Custom Designs: Very Specific Machine Dimensions and Operating Conditions.

Durability: Extremely Hardy Materials Used to Ensure Longevity.

2. Easy Installation: Modular Design Allows for Easy Assembly and Maintenance.

3. Ventilation System: Proper Air Flow Mechanisms Have Been Put in Place to Avoid Over Heating.

Applications of Acoustic Enclosures

Rest of The Word Very Application-specific Uses for Acoustic Enclosures Are:

1. Acoustic Enclosure for Machinery

Machines classified as heavy duty are said to produce a lot of noise that affects the output of the workers and attracts the noise regulations enforcement actions against the company. The adoption of our Acoustic Enclosure for Machines ensures that the facility experiences noise reduction without compromising operational efficiency. Be it compressors, turbines, or industrial generators; our units comply with more stringent noise control requirements.

2. Acoustic Enclosure for Blowers

These typically play an important role as blowers supply air in ventilation processes, drying applications, and other industries. However, they also produce unbearably loud noise. Our Acoustic Enclosure for Blower solutions are therefore acoustically designed to effectively reduce sound while allowing a free flow of air. These units are fully accepted in manufacturing, power generation, and chemical processing.

3. Echo Barriers for Outside Noise Control

We also have outdoor Echo Barrier products that are useful for enerpy and portable solutions. They are best applied in reconstruction sites, external events, or whenever any temporary setups are done that need noise-controlled environments. Their lightweight and fantastic sound-absorbing characteristics put them in a class of their own as compared to other products.

Benefits of Using Acoustic Enclosures

Advantages of Acoustic Enclosure Investing:

1. Safety improvements: traditional as well as modern methods of noise reduction greatly minimize the risk of hearing damage and assure the general well-being of each employee significantly.

2. Regulatory compliance: assists in meeting local or international noise control standards.

3. Increased efficiency from equipment: appropriately designed enclosures shut off the overheating and prolong machinery life.

4. Eco-friendly: reduced noise pollution, leading to a quieter and more sustainable living environment.

Why Choose Envirotech Systems Ltd for Acoustic Enclosures?

As reputed Acoustic Enclosure Manufacturer, Envirotech Systems Ltd excels due to the quality and innovative approaches. Here are the reasons why industries across the globe bank on us:

1. Tailored Solutions: Our proficient team cooperates with clients for various noise control encasement designs.

2. Fine Sound Materials: Our usage of finest sound-absorbing materials ensures durability.

3. Comprehensive Support: Starting from the very steps of consultation up to installation and maintenance-end-to-end solutions.

4. Eco-Friendly Design: Our design enclosures have less environmental and more efficient part to ensure a perfect blend.

Case Studies: Real-World Applications

1. Manufacturing Unit

Acoustic Enclosure Solutions for Machines on the Assembly Line. This is the company that approached us to develop well-known manufacturing sites that usually do very great work with their machines. After we installed it, the enclosure achieved noise reduction levels of up to 70%, making their workplaces safer, as well as the voices of employees happier.

2. Power Plant

We custom made an Acoustic Enclosure for a Blower, where the Air-filled Industrial Power Plant is facing severe noise pollution due to the noise generated by blowers. It not only catered to the attenuation of noise but also accorded comfort in the inside airflow for a blower's good performance.

3. Construction Site

This time, Reed Echo Barrier was placed at the construction site in a densely populated area. It has worked wonders, such as reducing noise complaints in the area. It shows how very well temporary solutions in noise control can work.

Maintenance and Longevity of Acoustic Enclosures

Regular maintenance is very significant for your Acoustic Enclosure to be productive for years. Below are some suggestions in this regard:

1. Consider Checking for Signs of Damage and Wear: Check for any damage or deterioration in the enclosure's material on a regular basis.

2. Clean Your Ventilation Systems: Follow airflow pathways and ensure free and unobstructed access to them.

3. Plan for Professional Maintenance: Scheduled inspections by professionals will reveal early warnings of upcoming failure.

Future Trends in Acoustic Enclosure Technology

With the changing industries, technology that involves the acoustic enclosure solutions is also evolving. Trends emerging in these sectors are as follows:

1. Smart Noise Measurements: Include IoT sensors for noise measurement in real-time.

2. Sustainable Materials: Products increasingly made of eco-friendly and recyclable materials.

3. Compact Design: It brings forth the use of compact enclosures without compromising performance.

Conclusion

Noise control is one of the very important aspects in the present day industrial operations, and the best solution would probably be the Acoustic Enclosures built by Envirotech Systems Ltd. We are so much proud to be one of the top leading Manufacturers of Acoustic Enclosures and offering a wide variety of sound solutions like Acoustic Enclosure for Blower, Acoustic Enclosure for Machines, and Echo Barrier in India. We are known for high quality, high-end innovation, and high sustainability.

Come join us for acoustic enclosure activities with us today, and you will get to see the effects of our expertise in your operations. Contact us at Envirotech Systems Ltd, to learn about our products and how we can help in your quieter, better, and efficient industrial locations.